I acquired, quite unintentionally, a Norinco Para 16” barrel SKS recently. Right off the bat it had an issue where it would disassemble itself. The trigger group inletting, was too large, allowing the trigger group to slide backwards out from under the retainer spring head. The quick and easy fix was to use a little wood epoxy and fill in and shape the area at the back of the trigger group. I did this and it fixed that issue.

My past experiences with Chi Com SKSs (late 80’s early 90’s) is that they really lacked in the accuracy department. Which got my little toad brain turning and wondering if bedding the action was a viable option. So, with some research on the internet, a discussion or 2 with knowledgeable friends, I decided to give it a shot. A quick disclosure, I do have some prior experience with bedding M1 Garands and M1As.

The first thing I noticed upon close examination of the stock was the front of the stock where it fit into the stock ferrule was a mess. It had some cracking and chipping as well as a small piece broke off when I was looking at it. I quickly cleaned and superglued that little piece back in place.

The next issue I noticed was the action when it was in the stock like to push towards the right.

Out came the sandpaper and Dremel tool and I identified and removed high areas and pressure points in the stock, until I got a neutral fit of the action in the stock. I worked on that most of the day, being careful not to remove too much material.

The next day’s agenda was to fix the front of the stock and here is the approach I took and why.

In bedding M1s and M1As the stock ferrules are not bedded, they are free floated. Generally, pressure is applied under the barrel with a fixture to place upward pressure on the barrel and downward pressure on the stock, so that when the front of the stock sets in the metal ferrule there is a constant downward pressure of the stock on the ferrule.

Examination of the SKS showed that the barrel was actually free floating from the chamber area to front ferrule. I grabbed the release agent and thoroughly coated the front stock ferrule. I let that set while I gathered up other items I would need and did some work on the front of the stock. I dremeled out a couple of small splits where the bayonet slot was and sanded the ferrule interface area of the stock.

I then mixed some bedding compound and applied it to the front of the stock, carefully filling in the areas near the bayonet slot. I placed two leather spacers in the stock to hold upward pressure on the barrel near the front of the forend and mated the stock to the ferrule. I then placed a small spacer under the heel of the receiver and locked the action in place. I then let the bedding dry 24hours. This is always the hard part, wondering if it will come apart, did I coat the metal good enough.

The good news is that it did come apart and turned out great, a little touch up sanding and bedding sprue removal and the bedding did a 100% repair on the little piece I had to glue back on. Now on to the preparation of the stock for bedding.

In bedding the M1/M1A, its important bed the receiver heel and front receiver lugs and if a rear lugged receiver those too. You also want to bed the receiver rails that sit on the stock. You actually use spacers that keep the rails off the wood so that it sets on the bedding material, same with the receiver heel. Unfortunately, this is not possible with SKS rails as the set in the stock, not on the stock, however it is possible to space the receiver heel when bedding.

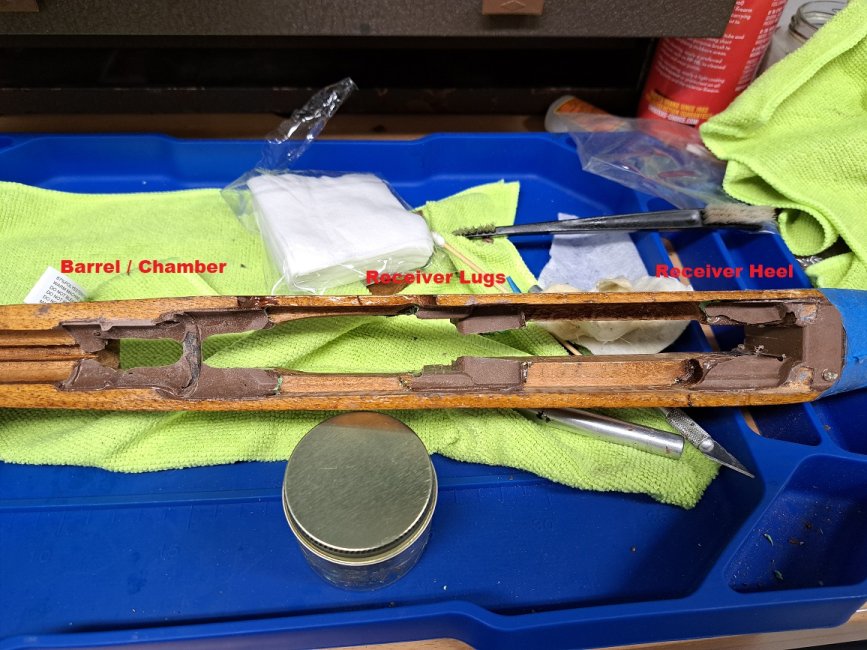

What I decide to bed and where on the SKS stock.

The receiver heel and the area just forward of it that has a shoulder that sets down in the stock.

The main vertical recoil lug that that has the action retaining spring.

The forward receiver lugs that also help hold in the trigger group and the magazine assemble.

The Barrel / Chamber and crossbolt area.

In bedding the M1/M1A small cuts in the stock about a ¼ inch deep are made in the areas where the bedding material will go. This in theory creates a stronger bond than just applying bedding material to a sanded flat service. So, I prepped this stock in the same way. A cut was made under the receiver heel, behind and in the corners of the vertical recoil lug area. In the area in front of the receiver heel were the receiver sets on an inletted shelf. The area on the front lugs were Dremeled out to allow more bedding material and cuts were made in the wood shelf behind them to strengthen the bedding. The large open areas were filled with play dough to keep the bedding material in place until it dried. The chamber area was rough sanded and relieved as much as possible as no cuts of any depth could be made in that area. After all the prep, the dust was cleaned and blown out of the stock with a compressor. At this time the wood epoxy that had been applied earlier to the trigger guard area was removed and that area cleaned up.

If you look at the picture of the stock after bedding and cleanup, you will see two small squarish spots of wood in the receiver heel area, one on either side. This is where I glued in with superglue two small spacers that lifted the receiver heel off the wood so that it would sit entirely on bedding material.

Bedding, all I have got to say is what a messy job, if you attempt something like this, keep rags and alcohol (the rubbing kind) handy as you will need them (you’ll definitely need the drinking kind afterwards). I liberally applied release agent, two coats minimum to all metal surfacers and filled any pin holes, et cetera with play dough. If you underuse the release agent or miss a spot you are going to have real problems. Note: Fill any areas in the stock with paly dough that you want to keep bedding material out of.

I applied the bedding into the areas, making sure I got enough in (a few spots could have used more). Since I had already done the stock ferrule fit, I placed my spacers in the barrel channel and squeezed the action into the stock. I flipped it on its back and shaped any bedding that I needed too or pressed more into areas that need it. When I was satisfied with it, I placed the magazine assembly in position, then the trigger guard/assembly in position, making sure it was as far forward as possible and engaged in the forward lugs all the way. I then latched the trigger assembly and proceeded to apply fresh bedding behind it (make sure you coat that spring good), to fix the original disassembly issue. I let it dry 24 hours.

I literally had to beat it out of the stock with a wood dowel and a hammer, that is a very good sign. It did release, with no damage to the stock or any components. Talk about breathing a big sigh of relief.

I then did clean up on the bedding and cleaned the release agent off the action (what a pain in the ass) as it was a wax type of release agent. I did have to clean out a few places, especially the release spring and around the front lugs, but since they had release agent applied it was all pretty easy. The stock is a very tight fit, it requires a hammer to knock the action out it and a hammer to tap back into the stock.

Now for the proof.

Picture 1: Bedded and repair front stock.

Picture 2: Cleaned up bedding

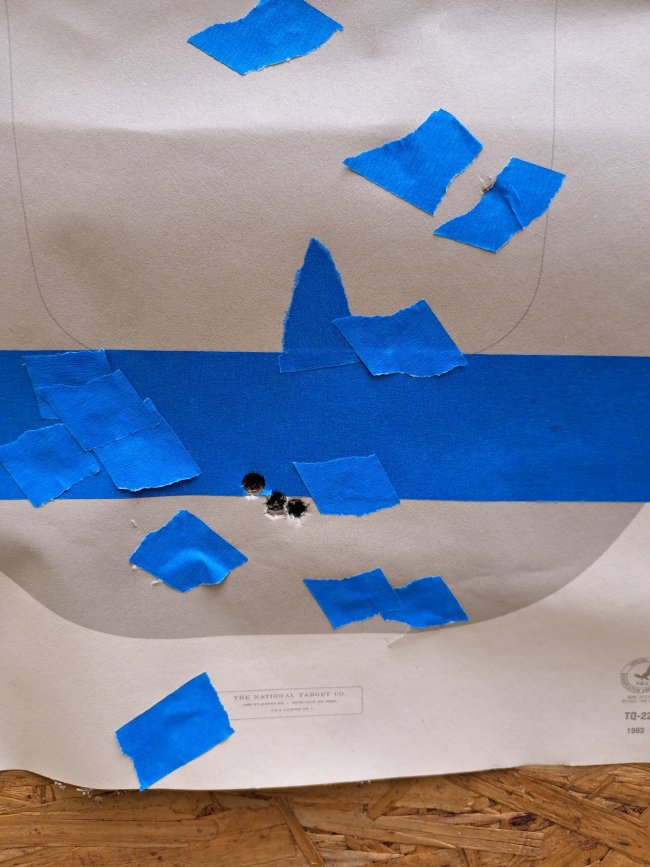

Picture 3; 3 rounds at 25 yards

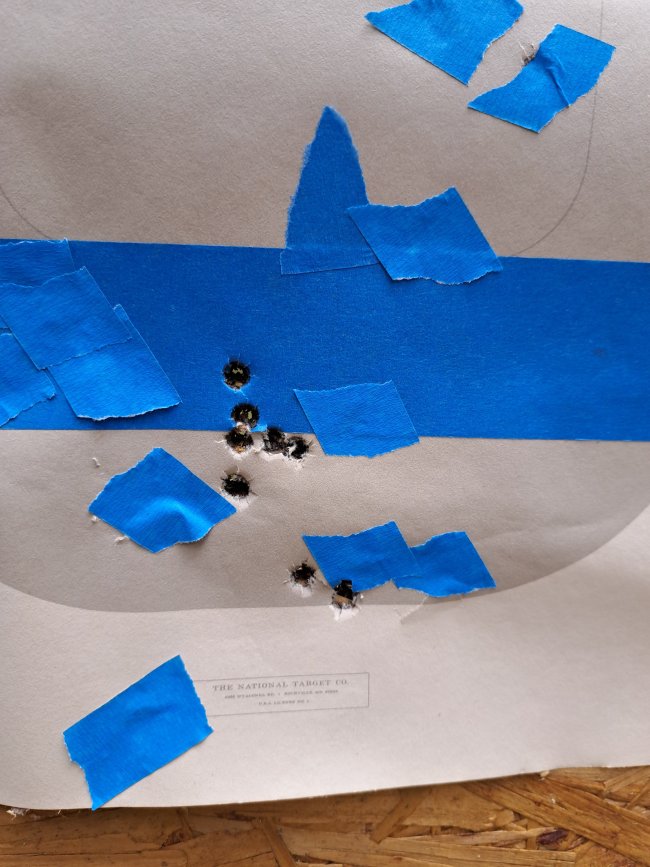

Picture 4: More at 25 yards.

Picture 5: 5 rounds at 100 yards, the one flyer to the left I believe was ammo related.

4 rounds ejected to 2 o’clock but that shot ejected over my head to 7 o’clock.

This was ammo I bought off of a board member for cheap and was stored loose, in a ammo can for a unknown number of years. Wolf 122grn JHP steel case.

I didn’t think it was bad for iron sights and 67 ½ year old eyes.

All in all, I’m pretty pleased with the results.

My past experiences with Chi Com SKSs (late 80’s early 90’s) is that they really lacked in the accuracy department. Which got my little toad brain turning and wondering if bedding the action was a viable option. So, with some research on the internet, a discussion or 2 with knowledgeable friends, I decided to give it a shot. A quick disclosure, I do have some prior experience with bedding M1 Garands and M1As.

The first thing I noticed upon close examination of the stock was the front of the stock where it fit into the stock ferrule was a mess. It had some cracking and chipping as well as a small piece broke off when I was looking at it. I quickly cleaned and superglued that little piece back in place.

The next issue I noticed was the action when it was in the stock like to push towards the right.

Out came the sandpaper and Dremel tool and I identified and removed high areas and pressure points in the stock, until I got a neutral fit of the action in the stock. I worked on that most of the day, being careful not to remove too much material.

The next day’s agenda was to fix the front of the stock and here is the approach I took and why.

In bedding M1s and M1As the stock ferrules are not bedded, they are free floated. Generally, pressure is applied under the barrel with a fixture to place upward pressure on the barrel and downward pressure on the stock, so that when the front of the stock sets in the metal ferrule there is a constant downward pressure of the stock on the ferrule.

Examination of the SKS showed that the barrel was actually free floating from the chamber area to front ferrule. I grabbed the release agent and thoroughly coated the front stock ferrule. I let that set while I gathered up other items I would need and did some work on the front of the stock. I dremeled out a couple of small splits where the bayonet slot was and sanded the ferrule interface area of the stock.

I then mixed some bedding compound and applied it to the front of the stock, carefully filling in the areas near the bayonet slot. I placed two leather spacers in the stock to hold upward pressure on the barrel near the front of the forend and mated the stock to the ferrule. I then placed a small spacer under the heel of the receiver and locked the action in place. I then let the bedding dry 24hours. This is always the hard part, wondering if it will come apart, did I coat the metal good enough.

The good news is that it did come apart and turned out great, a little touch up sanding and bedding sprue removal and the bedding did a 100% repair on the little piece I had to glue back on. Now on to the preparation of the stock for bedding.

In bedding the M1/M1A, its important bed the receiver heel and front receiver lugs and if a rear lugged receiver those too. You also want to bed the receiver rails that sit on the stock. You actually use spacers that keep the rails off the wood so that it sets on the bedding material, same with the receiver heel. Unfortunately, this is not possible with SKS rails as the set in the stock, not on the stock, however it is possible to space the receiver heel when bedding.

What I decide to bed and where on the SKS stock.

The receiver heel and the area just forward of it that has a shoulder that sets down in the stock.

The main vertical recoil lug that that has the action retaining spring.

The forward receiver lugs that also help hold in the trigger group and the magazine assemble.

The Barrel / Chamber and crossbolt area.

In bedding the M1/M1A small cuts in the stock about a ¼ inch deep are made in the areas where the bedding material will go. This in theory creates a stronger bond than just applying bedding material to a sanded flat service. So, I prepped this stock in the same way. A cut was made under the receiver heel, behind and in the corners of the vertical recoil lug area. In the area in front of the receiver heel were the receiver sets on an inletted shelf. The area on the front lugs were Dremeled out to allow more bedding material and cuts were made in the wood shelf behind them to strengthen the bedding. The large open areas were filled with play dough to keep the bedding material in place until it dried. The chamber area was rough sanded and relieved as much as possible as no cuts of any depth could be made in that area. After all the prep, the dust was cleaned and blown out of the stock with a compressor. At this time the wood epoxy that had been applied earlier to the trigger guard area was removed and that area cleaned up.

If you look at the picture of the stock after bedding and cleanup, you will see two small squarish spots of wood in the receiver heel area, one on either side. This is where I glued in with superglue two small spacers that lifted the receiver heel off the wood so that it would sit entirely on bedding material.

Bedding, all I have got to say is what a messy job, if you attempt something like this, keep rags and alcohol (the rubbing kind) handy as you will need them (you’ll definitely need the drinking kind afterwards). I liberally applied release agent, two coats minimum to all metal surfacers and filled any pin holes, et cetera with play dough. If you underuse the release agent or miss a spot you are going to have real problems. Note: Fill any areas in the stock with paly dough that you want to keep bedding material out of.

I applied the bedding into the areas, making sure I got enough in (a few spots could have used more). Since I had already done the stock ferrule fit, I placed my spacers in the barrel channel and squeezed the action into the stock. I flipped it on its back and shaped any bedding that I needed too or pressed more into areas that need it. When I was satisfied with it, I placed the magazine assembly in position, then the trigger guard/assembly in position, making sure it was as far forward as possible and engaged in the forward lugs all the way. I then latched the trigger assembly and proceeded to apply fresh bedding behind it (make sure you coat that spring good), to fix the original disassembly issue. I let it dry 24 hours.

I literally had to beat it out of the stock with a wood dowel and a hammer, that is a very good sign. It did release, with no damage to the stock or any components. Talk about breathing a big sigh of relief.

I then did clean up on the bedding and cleaned the release agent off the action (what a pain in the ass) as it was a wax type of release agent. I did have to clean out a few places, especially the release spring and around the front lugs, but since they had release agent applied it was all pretty easy. The stock is a very tight fit, it requires a hammer to knock the action out it and a hammer to tap back into the stock.

Now for the proof.

Picture 1: Bedded and repair front stock.

Picture 2: Cleaned up bedding

Picture 3; 3 rounds at 25 yards

Picture 4: More at 25 yards.

Picture 5: 5 rounds at 100 yards, the one flyer to the left I believe was ammo related.

4 rounds ejected to 2 o’clock but that shot ejected over my head to 7 o’clock.

This was ammo I bought off of a board member for cheap and was stored loose, in a ammo can for a unknown number of years. Wolf 122grn JHP steel case.

I didn’t think it was bad for iron sights and 67 ½ year old eyes.

All in all, I’m pretty pleased with the results.