-

Please read the new forum rules! REQUIRED!

Click Here: https://www.gulfcoastgunforum.com/threads/general-forum-rules-code-of-conduct.70770/

-

New Reloading Sticky Thread for Trading, Swapping Gear, etc.

https://www.gulfcoastgunforum.com/threads/reloading-components-for-trade-item-value-and-photo.104847/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

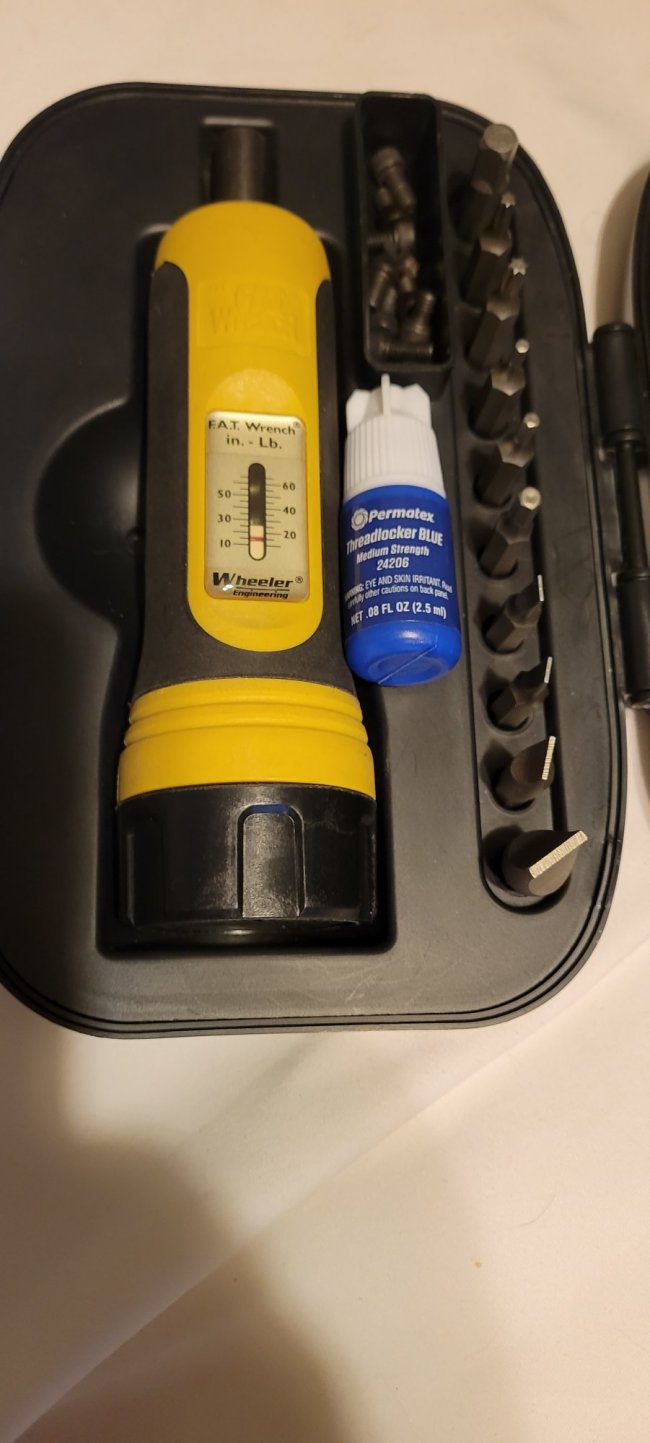

Torque screwdriver recommendations

- Thread starter nwfdub

- Start date

The #1 community for Gun Owners of the Gulf Coast States

Member Benefits:

Fewer Ads! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

Rebel_Rider1969

Well Known Nuisance

I use a Allen key. Holding the short end I crank it as best I can holding on the short end. Not very scientific but seems to work. Hand strength dependant. Ymmv.

A little trick I learned also. Is these screws don't come with loctite of any sort on them from the factory. Seeing how you will likely want to take it off often and swap guns n stuff, you don't really want to use a permanent setting kind of glue. So I take a dab of E6000 fabric multi purpose glue and put a tiny dab on screws. As you shoot these love to rattle loose. This type of glue is clear and rubbery when it dries. It's just gummy enough to keep them held but forgiving and won't lock anything up. They may make a better proper version of this glue for this job but it's just what I've found to work that I had laying around at the time. Also press the optic forward against the picrail as you tighten it. Having it pressed on them keeps it from shifting under recoil. Anyways a little soft glue makes it so I don't have to rely on a crazy tight torque and possibly strip things. I wouldn't use this on things that gets hot tho.

Sent from my SM-G988U using Tapatalk

Sent from my SM-G988U using Tapatalk

Rebel_Rider1969

Well Known Nuisance

Yeah!!!I use an impact driver!

I found one at walmart.com that was inexpensive (If I remember it was $30 or less) and works great. Brand is "Autlead" I checked the inch pounds against a 1/4" torque wrench that I have and they were the same so I guess it's fairly accurate. Has a "T" shape so easy to hold and torque properly

Not cheap--but CDI torque products are excellent. No spring, so calibration is not required (downfall of most wrenches/drivers). Mine seems very repeatable, and they have a big range of torque values available.

Purple threadlocker is good too if you feel the need to threadlock. Minimal resistance when you go to remove it.

This style, but range on mine is much smaller.

Purple threadlocker is good too if you feel the need to threadlock. Minimal resistance when you go to remove it.

This style, but range on mine is much smaller.

Last edited:

zdiver99

Master

I use a TEKTON 1/4 drive torque wrench. Model number TRQ-21101, 10-to-150-inch pounds. Online they are $52. If you need a set of 1/4, 3/8, 1/2-inch drive, they have the set at $148.00

Can be found at https://www.tekton.com/

Can be found at https://www.tekton.com/

Yeah I'll have to get some tips when ya come by on that. So far all my stuff is red dots etc. It hurts to say it, but they're all 400 dollarish ones roughly. Hard to believe that's just for basic budget stuff mainly. Optics are definitely an expensive game. When i set up a long range one I'll have to definitely upgrade the Allen wrench!

Sent from my SM-G988U using Tapatalk

Sent from my SM-G988U using Tapatalk

full send...I use an impact driver!

glad you made this thread i just broke a sig optic lol

If you used an impact driver, I understand @Duckyou is issuing refunds.

But processing times....could be a while.

Latest posts

-

-

-

-

-

FS: LOK Grips Beretta 92X | Vertec Bogies (BVB-CM) - $25 *Pensacola*

- Latest: TackleberryMCS

-

WTT: MAGPUL GL-9 17-rd. PMAGs for Glock 17 Gen5 17-rd. magazines

- Latest: TackleberryMCS

Staff online

-

Richard LipsMake America Florida